Wheel Measurements

Helping you understand alloy wheel measurements...

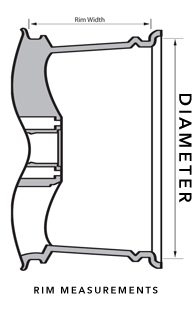

What is Diameter?

The diameter of a wheel is the width across from directly opposite parts of the rim – essentially how “big” the wheel is. When people talk about “rolling on 22’s”, they are essentially referring to their vehicle having 22″ diameter wheels! Our wheel designs come in a variety of diameters and some may not be suitable for your vehicle as once fitted, they may rub on the wheel arches. We use industry data to tell us, from experience, which wheels will be suitable for your vehicle.

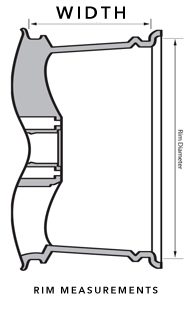

What is Width?

Width is a fairly simple starting point for analysing how wheels fit to your vehicle. This is simply the width or depth of the wheel from front (face) to back, the distance between the tyre mounting flanges. Many people tend to put wider wheels on their vehicle as it is widely accepted that this will increase grip and stability as there is more tyre surface in contact with the road.

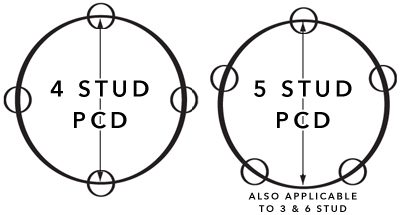

What's a PCD?

PCD stands for Pitch Circle Diameter and is measured in millimetres (mm). It is one of the key measurements taken into account when finding wheels to fit your vehicle. Manufacturers all use different PCDs, and often the PCDs also vary by model and year of vehicle. In general, the number of holes for most vehicle in today’s market ranges from 3 to 8. The PCD of a wheel is an imaginary circle that passes through the centre of each mounting hole. It is essential that when fitting aftermarket alloy wheels, the new wheel is of the correct PCD for the vehicle. For 4-stud wheels, this can simply be calculated by measuring from the middle of the top left stud hole to the centre of the bottom right stud hole. For 3, 5, 6, and 8-stud applications, the imaginary circle must be drawn through the centre of each stud hole to determine the correct PCD.

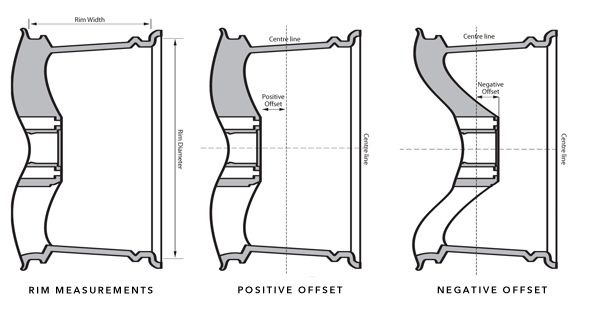

What is Offset?

The offset of a wheel is the measurement from a wheels imaginary centre line to the mounting face, and is commonly shown as ET. For most modern vehicles the offset will be positive, which means the mounting face is forward of the centre line, bringing the wheel further under the bodywork of the car. Older cars and some 4×4 vehicles will have negative offset, which pushes the wheel outwards from the car’s bodywork. Aftermarket wheels may have a lower offset than the vehicles standard wheels and this is to accommodate the fact that the aftermarket wheel is invariably wider than the vehicles standard wheels. It must be stressed that too great an offset reduction will affect the car’s stability and roadholding and will cause accelerated wear to drive-train and suspension components.

Zero Offset – The plane of the hub mounting surface is even with the centerline of the wheel.

Positive Offset – The plane of the hub mounting surface is shifted from the centerline toward the front or face of the wheel.

Negative Offset – The plane of the hub mounting surface is toward the back or brake side of the wheel’s centerline.